Introduction

Project Management refers to initiation, planning, management as well as execution of all the stages of a certain project(Harrison and Lock, 2017). It is a crucial aspect determining the scope up to which the project would be successful and effective. All the stages in operations and project management is concerned to appropriately achieve a set task. The project is based on Morphy Richards, which an home appliance firm operating in Mexborough, United Kingdom. The company is planning to move in to Large Screen Television Market. The report will cover critical evaluation of theories like six sigma and and lean principles and effectiveness of continuous improvement plan. It would also include application of each stage of Project Life Cycle (PLC) and critical analysis of how using different models and theories, PLC would differentiate between large and small scale companies.

Increase Your Odds of Success With Our

- Scholastic academic documents

- Pocket friendly prices

- Assured reliability, authenticity & excellence

Task 1

P1. Review and critique of the implementation of operations management principles

Operations Management means the administration of various organisational practices to maximise the efficiency achieved within a business (Mahadevan, 2015). It is a very crucial practice which is necessary to carry out procedures and practices with utmost precision. For Morphy Richards., there are various theories that are need to be evaluated which are mentioned below:

- Six Sigma:

This is a methodology which is concerned with enhancing effectiveness and improve services and products of a company. Six Sigma have two different methodologies which are DMAIC and DMADV. Since the firm is entering into large scale television market, it is required from the company to research and develop new products. For the same, DMADV methodology would be used which is mentioned below:

- Define:This stage is concerned with defining the project goals and objectives that are required to be addressed. For this, Morphy Richards needs to consider aspects that are imperative for customers. This step also undertakes creation of teams and strategies for further implementation.

- Measure:This stage requires the firm to determine various metrics for data collection and record useful information in ways which could help the company to effectively conduct the remaining information (Kerzner and Kerzner, 2017).

- Analyse:This step undertakes analysis of the processes which meets needs of the customers and opportunities. The data and information gathered is effectively utilised which could assist the manager to enhance the quality and manufacturing process of large screen televisions.

- Design:This stage undertakes measurement of tests as per the wants of customers and required standard of the project.

- Validate:This step is continuous in nature and regular adjustments are made which as per the required modifications to satisfy the goals of the project.

Critical Evaluation of Implementation Six Sigma:

- Six Sigma is quite useful to improve the products and services of the company and develop offerings as per the required demands of customers. However, it induces rigidity in organisational processes and could cause delay and issues in creativity.

- This methodology focuses completely on satisfying the needs of the customers and the policies set under this approach effectively determines the same. However, these policies might assist the company in looking towards extreme and expensive measures rather than inexpensive and effective methods. (Swink and et. al., 2017)

- Lean Principles:

The inception of these principles was from manufacturing practices, however, recently the process has witnessed transformation as it is considered with continuous improvement of business processes. There are various principles which comes under this element and are viable for Morphy Richards. These principles are mentioned below:

- Value:The first step undertakes understanding the concept of value which the customer is willing to pay for the large screen television. Establishment of such factor would determine Morphy Richards to develop a top-down price for their televisions and identify the cost of its production.

- Value Stream Mapping:In this stage, the value as per the customers are taken as a reference point and the firm could determine the tasks that would contribute to these values. The tasks not contributing to such value re considered as waste and eventually eliminated.

- Flow Creation:After all the wastes or non-contributing aspects are removed, the firm is required to determine the flow of remaining products and processes. In this manner, this would be able to regulate the operations that could maximise the efficiency (Todorović and et. al., 2015).

- Establishing Pull:This step is considered to reduce the Work In Progress and inventory items to ensure smooth and effective workflow through availability of requisite information and equipments.

- Perfection:As the most crucial step of the whole process, this stage needs Morphy Richards to apply culture and practices within the organisation which is effective and ensures utmost quality in development of their Large Screen Televisions.

Critical Evaluation of Implementation of Lean Principles:

- Morphy Richards could appropriately apply these principles in development of their Large Screen Televisions as it ensures effective minimisation of waste and conduction of the whole process with just contributing materials and personnels. However, the implementation is very risky as a little error in the equipments or processes could cause major inconsistencies in the whole project.

- The focus of these principles are completely on developing effective customer relationships. However, there are chances of delivery inconsistencies which would limit the confidence of customers on the company (McArthur, 2015).

- Total Quality Management:

This method undertakes maximisation of quality of products as well as services of the company. Morphy Richards, through TQM could focus on delivering the best quality of large screen televisions to the customers. This needs the company to adopt processes and equipments that help the company to manage the quality and standard of their televisions throughout the development process. It also requires the company to determine measurable aspects on which they could manage and measure quality.

Want to Join the Circles of

HIGH ACHIEERS?Make it a reality with our EXPERTS

Order NowTask 2

P2. Continuous Improvement Plan for Morphy Richards

To manage the overall progress of the company, it is essential for the firm to effectively develop a continuous improvement plan to manage and encourage practices that could maximise the efficiency and effectiveness of business processes (Artto, Ahola and Vartiainen, 2016). The major aspects of a CIP is concerned with cost, quality, safety and delivery of the offerings by a company. The continuous improvement plan for Morphy Richards is mentioned below:

|

BASIS |

APPROACHES / PRINCIPLES |

IMPLEMENTATION |

|

Quality |

Morphy Richards could apply Total Quality Management to maximise the quality of Large-screen Televisions which they will be providing to their customers. |

Implementation of Total Quality Management would enable the organisation to ensure top quality as per the industrial standards and demands of the customers. Moreover, it would allow the firm to gather |

|

Cost |

To minimise the cost of production, principle of Variance could be applied by the organisation to ensure continuous improvement. |

Principle of Variance could ensure flow of creative and innovative ideas which could ensure employment and implementation of cost-effective methods and techniques for the production and distribution of Televisions. |

|

Delivery |

As provision of the television is yet another important aspect, Six Sigma Methodology could be used by the company. |

This methodology could enable Morphy Richards to analyse, design and validate better and appropriate delivery techniques and methods of delivery of their Large-screen Televisions. |

|

Safety |

To eliminate wastage from the process and development procedures, Lean Principles could serve as the most viable and appropriate methodology to ensure safety in their Large-screen Televisions. |

Lean Principles ensures complete minimisation of any element within the product or the process which does not contribute to the successful production (Chevalierand et. al., 2015). Implementation of the same could enhance the scope for the firm to concentrate more on its safety and acquiring appropriate measures that could establish the culture within Morphy Richards where equipments and processes emphasize on adopting effective safety measures in the product itself, its development processes and delivery. |

Effectiveness of Continuous Improvement Plan:

It is essential for Morphy Richards to analyse the effectiveness of its Continuous Improvement Plan to ensure the production and delivery of company's televisions as per set standards, customer expectation and competitive business environment (Kundu and et. al., 2015). The effectiveness of CIP is measured on various Operations Management Principles which are as follows:

- Organisation: This principles require all the elements and factors of the project to be consistent as well as predictable. In addition, business processes present in manufacturing of Large-screen Televisions would be interconnected. Continuous Improvement Plan within the firm have been quite effectively organised and usage of Six Sigma as a methods allowed the firm to analyse the factors effectively.

- Accountability: Manager at Morphy Richards are required to allot roles and responsibilities and set out clear metrics to judge the effectiveness of the performance of employees throughout the project. In addition, they are also required to monitor and supervise their work in relation to enhancing the overall operation. Lean Principles helped the company in achieving improvement in employee performance in ways in which it contributed to the company's success.

- Variance: It is concerned with the company limiting the cost of production for their television, which requires Morphy Richards to apply creative processes and methods. As a principle, it is required to be encouraged. By applying this principle, the firm was able to manage the cost of production without reducing the quality of televisions.

- Change: This principle requires the company to analyse and assess all its processes and equipments as per the current requirements and feasibility of the project. Thus, it is essential for the company to apply methods and aspects to satisfy the changing and dynamic factors of the market. This principle was well satisfied by applying Total Quality Management method. This is because it enabled the firm in determining latest techniques and equipments which could enhance the quality of production and product and keep up with the consistency.

We believe in serving our customers with the most reliable assignment help

Task 3

P3. Application of Project Life-cycle (PLC)

Every project has a specific structure and a life cycle which undertakes each stage of the project from its inception to closure. It is imperative that each stage is effectively planned to maximise the opportunities to achieve success. Each stage holds significant value in the project and it is imperative that the company follows effective tools, methodologies and leadership which broadens the scope of its success (Glukhov, Ilin and Levina, 2015).

Morphy Richards is planning to enter Large-screen Television markets where the firm would manufacture televisions within minimum size of 52 inches. The firm is required to set up effective Project Life-cycle to execute the overall business plan. Each stage of this life-cycle in context with the new product development of this company is discussed below:

- Initiation:It is the very first phase of any project. It requires the company to define its project of developing large scale television. This stage requires stakeholders of the company to authorise and agree for its further execution. Leadership at this stage should be democratic. The reason for the same is to ensure effective planning of development of Large-screen Television where employees of the organisation could give their inputs regarding the best and the most appropriate methods to further execute the project. Morphy Richards could use Six Sigma as an approach to effectively measure, analyse and validate the whole project at this stage. The company could use Slack as an effective tool during the initiation phase which could enable the company to establish appropriate communication channel for the company.

- Planning:After authorisation to execute the project further, the second stage emphasises on planning. The organisation, in this step is needed to determine resources which would help in the further execution of Large-screen Television development. These resources could be equipments, personnels, skills, knowledge, technology, finance, etc. this stage also undertakes development of a detailed project plan which would provide directions and a pathway for Morphy Richards to conduct the project. At this stage, the firm could use Lean Principles to plan effective ways and methods that reduce the waste and enhance effectiveness. Organisation could use Workfront as a tool to track the project as per the allotted time and to monitor the overall project budget. Strategic leadership style could be adopted by managers which would be viable at this stage to develop strategies which required by the company to successfully develop the new product.

- Execution:As the name suggests, this step is detailed with the overall execution of the development of televisions. In this, customers and the manager allots roles and responsibilities to the project team and allocate various resources for them to smoothly conduct their activities. This stage is heavily dependant on the planning stage. The pattern and methods used to execute the project is completely as per the set standards in the previous step. Firm could create risk management logs, checklists, WBS and other aspects which would present as effective tools and techniques for perfect development and distribution of Large-screen Televisions. Leadership used in this stage is quite important as it would determine the success of overall project. Choosing an ineffective style of management could be very harmful for Morphy Richards and development of its new products. Autocratic Style of Leadership could serve well in this stage as clear instructions are required to be given to the project team along with effective monitoring of performances. In addition, the most viable approach would be Total Quality Management to develop the televisions with utmost quality.

- Closure:This is the final step which arises when the final product, television in this case, gets delivered to its customers. Stakeholders are communicated regarding the very same and the resources are then released to other projects with the company. This step would need Morphy Richards to evaluate its effectiveness. The inconsistencies, shortfalls and shortcomings of the Large-scale Televisions development could set an example for the company in order to ensure effectiveness in its upcoming projects (McCluskey and Vallati, 2017).

BusinessCase:

|

CompanyOverview |

Morphy Richards Ltd. is a home appliance company which serves coffee makers, kettles, toasters and other electrical appliances. The firm was found in 1959 and provides effective after sales services too (Company Overview of Morphy Richards Ltd, 2019). |

|

Vision and Mission |

The vision of the company is to provide its top quality products to its customers worldwide. Mission for the same is to implement innovation in their processes and elegance and convenience to modern households. |

|

Objectives |

Through Large-screen Televisions, the objective of Morphy Richards is to enhance the television viewing experience for households by providing them with utmost clarity. |

|

Strategy |

The company is adopting latest technical methods to produce these televisions and using advanced technologies within their television screen to help them stand against the crowd. |

Project Plan:

|

Cost |

For development of large-screen televisions, Morphy Richard the cost to be almost between £12,000-18,000. |

|

Communication |

Since it is a vital strategy for the project, the company would be having internal meetings and effective horizontal, vertical, internal as well as external communication to ensure smooth running of operations for this project. |

|

Quality |

Methods like Total Quality Management, Artificial Intelligence and Automation are implemented by the company to maintain top quality standards of their Televisions. |

|

Scope |

The firm is hiring effective resources, financial, human and technological in the development of new product and different techniques throughout its development phases to ensure its success. |

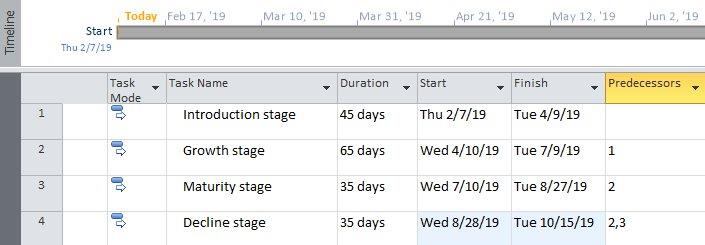

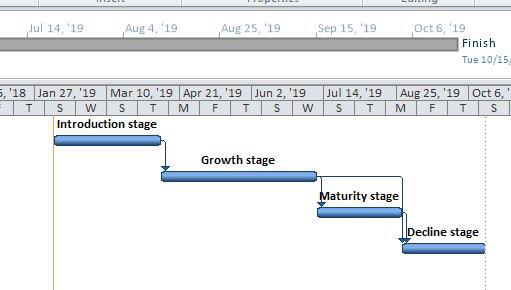

Gantt Chart:

Illustration 1: Gantt Chart

Illustration 2: Gantt Chart

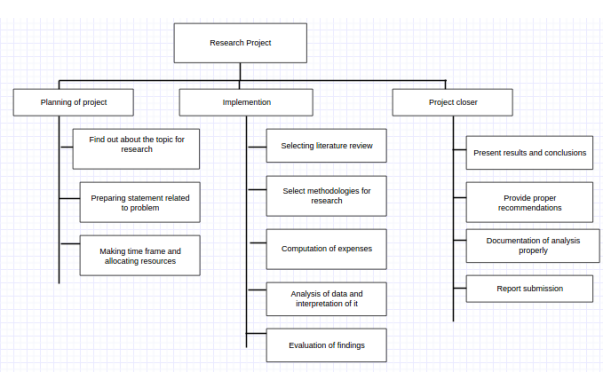

Work Breakdown Structure:

Illustration 3: Work Breakdown Structure

Task 4

P4. Review and Critique effectiveness of Project Life-cycle (PLC)

It is very crucial for companies to effectively analyse effectiveness of stages of Project Life-Cycle as it is very important for firms to get each stage right as per the required standards of the project. For Morphy Richards, the effectiveness of PLC is mentioned below:

- The initiation phase focused completely on developing a framework of the project for which it adopted six sigma and democratic leadership. However, too much access to power and development process might cause certain inconvenience among employees while performing certain activities when tasks are allotted in the future. On the other hand, six sigma is a very viable approach for the stage, however, it might fail to analyse the quality standards required to be achieved and thus, might be stressful to analyse such a crucial factor in later stages. Thus, the company must take all the aspects in concern while presenting the plan to stakeholders.

- The planning stage used Strategic leadership as well as lean principles. While the leadership could help the company develop effective strategies regarding production processes, lean principles, while satisfying its agenda of removing waste and creating utmost value, might add to the cost of production later where cost-effective alternatives could also be used. Thus, the firm must analyse methods that would provide maximum value to production and yet doesn't add too much on the cost.

- In execution process, Morphy Richards has used Total Quality Management as a strategy and Autocratic Leadership. While TQM would allow the company to manage its quality, it might add to the cost later on as it would insist on adopting most advanced processes and equipments for production of televisions. Autocratic Leadership too could add rigidity to the project as no innovative method could be utilised if not approved by the manager (Kerzner, 2018). It is however, recommended that the firm adopts flexible methods and must consider input from employees to effectively develop the televisions.

However, it is crucial to determine how the approaches would effectively differentiate between small and large projects. The differentiation is mentioned below:

|

Basis |

LargeProject |

Small Project |

|

Six Sigma |

Within a large project like that of development of Large-scale Television, this approach is useful to analyse, design and validate standards of the product as per the customer needs and wants. |

In small projects, like that of an electronic appliance company producing and distributing televisions to its customers, it would help the company develop effective customer relationships, eliminate defects as well as ensure timely delivery. |

|

Total Quality Management |

Projects like Large-Scale Televisions requires adequate resources, funds, equipments, technologies, etc. to ensure desired quality standards. Implementation of total quality management in such project would allow the firm to develop the same using extensive and advanced techniques which could produce results as per the market demands and immediate technological needs of customers (Heldman, 2018). |

For instance, if the firm is planning to ensure top quality safety measures in its toasters and kettles. Without incurring more resources and effective managerial expertise, the firm could implement this technique through innovation and flexibility. |

|

Lean Principles |

Implementation for these principles would be on a large scale where every aspect and resource would be analysed and non-contributing factors and processes would be removed to ensure effective development of Large-screen Televisions. |

For instance, the firm could apply this principle and remove necessary stickers over the televisions describing its specifications along with modules for the same. |

Conclusion

Thus, it is concluded that operations and project management is necessary to effectively carry out various projects effectively. Principles like six sigma, Total quality management and lean principles help companies to develop the projects as per the set standards and with utmost quality. Continuous Improvement Plan help the firm to ensure consistent improvements in product development process and quality. Project life-cycle determines stages of product development and provides structure to the company to work upon. Lastly, various methodologies and approaches are required to be analysed effectively to determine the shortcomings and ensure improvement in project management.

References

Books and Journals

- Artto, K., Ahola, T. and Vartiainen, V., 2016. From the front end of projects to the back end of operations: Managing projects for value creation throughout the system lifecycle. International Journal of Project Management. 34(2). pp.258-270.

- Chevalier, P., and et. al., 2015. Revenue management for operations with urgent orders. European Journal of Operational Research. 240(2). pp.476-487.

- Glukhov, V.V., Ilin, I.V. and Levina, A.I., 2015, August. Project management team structure for internet providing companies. In Conference on Smart Spaces (pp. 543-553). Springer, Cham.

- Harrison, F. and Lock, D., 2017. Advanced project management: a structured approach. Routledge.

- Heldman, K., 2018. Project management jumpstart. John Wiley & Sons.

- Kerzner, H. and Kerzner, H.R., 2017. Project management: a systems approach to planning, scheduling, and controlling. John Wiley & Sons.

- Kerzner, H., 2018. Project management best practices: Achieving global excellence. John Wiley & Sons.

- Kundu, A., and et. al., 2015. A journey from normative to behavioral operations in supply chain management: A review using Latent Semantic Analysis. Expert Systems with Applications. 42(2). pp.796-809.

- Mahadevan, B., 2015. Operations management: Theory and practice. Pearson Education India.

- McArthur, J.J., 2015. A building information management (BIM) framework and supporting case study for existing building operations, maintenance and sustainability. Procedia Engineering. 118. pp.1104-1111.

- McCluskey, T.L. and Vallati, M., 2017, June. Embedding automated planning within urban traffic management operations. In Twenty-Seventh International Conference on Automated Planning and Scheduling.